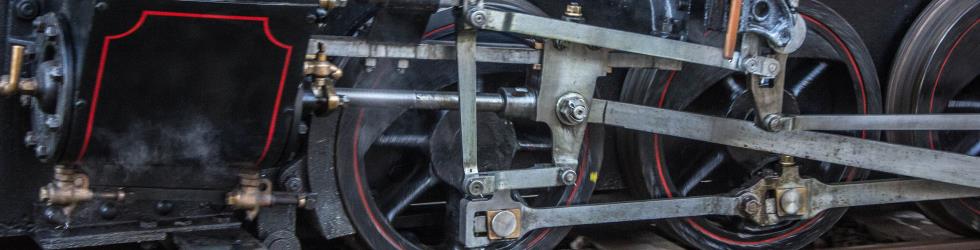

A mite chilly down The Valley at the weekend, but the biggest job was able to be done indoors. This was accompanied by a space heater which seemed to have been recycled from one of the Space Shuttle booster rockets. The job itself was to lift the Hudswell steam loco and investigate the lubrication arrangements for the rear axle. This all started after a memorable and slightly nerve-shredding visit with the loco to Leighton Buzzard back in 2016. Reckoned to be the most demanding 2’0″ gauge line in the UK (others may disagree), the Hudswell had problems with the rear axleboxes overheating badly. The loco has been invited back to Buzzard, and we didn’t want to commit to that without understanding the reasons for the 2016 problems. Lifting the loco quickly revealed the absence of an important oil groove in the bearing brasses – a simple problem easily rectified. Peace of mind then required checking the other wheelsets. This proved to be wise, as the same feature was absent to varying degrees in the other bearings.

Other activities progress in parallel; for example, a passenger diesel training & assessment session was run. Unfortunately that cannot be done indoors with a space heater/rocket booster, however desirable that may seem.